Modulating control valves plays a crucial role in managing the flow of feedwater and steam in a combustion boiler system. These valves help maintain the desired levels of water and steam within the boiler by continuously adjusting the flow rates according to the system's needs.

- Feedwater Flow Control: The feedwater, which is water fed into the boiler for conversion into steam, must be carefully controlled. A modulating control valve regulates feedwater flow into the boiler, which is critical because the amount of feedwater entering the boiler should match the steam demand from the process. If the feedwater supply is too low, the boiler can run dry, causing damage to the boiler tubes and other components. Conversely, the feedwater supply is too high, which can cause overfilling and unnecessary pressure on the boiler.

- Steam Flow Control: The steam generated in the boiler provides various processes like heating, power generation, etc. The modulating control valve regulates the steam flow from the boiler to the process. It adjusts the steam flow rate according to the process requirements, ensuring the process receives the correct amount of steam at the required pressure and temperature.

The operation of modulating control valves is typically automated, controlled by a control system that continuously monitors various parameters like boiler pressure, steam demand, water level, etc., and adjusts the valve position accordingly, ensuring optimal boiler operation, energy efficiency, and safety.

In summary, modulating control valves plays a crucial role in regulating the flow of feedwater into the combustion boiler and the steam flow from the boiler to the process. Proper operation of these valves is essential for the efficient and safe operation of the boiler system.

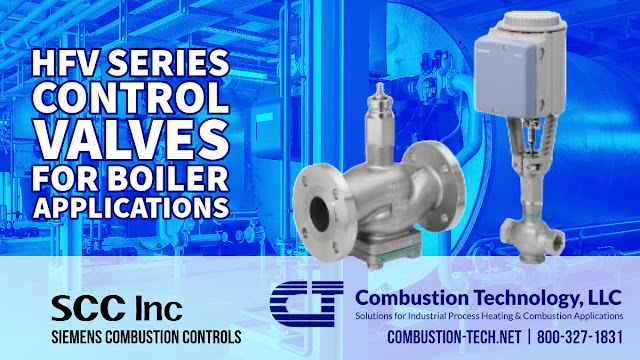

The Siemens Combustion Controls HFV series control valves are ideally suited for applications that involve the throttling and shutting off water or steam flow in boiler feedwater or steam flow systems. These valves operate using a Siemens SKB/C/D electronic actuator. The HFV control valves are available in a variety of sizes, ranging from 1/2" to 2" NPT (National Pipe Thread) and 1/2" to 4" flanged, with pressure ratings of either 150# or 300#.

HFV Series Control Valve Features

- Up to 150 psi differential across the valve when modulating.

- High close-off pressure.

- Stainless steel body, stem, and plug.

- Linear or equal percentage flow characteristic.

- ANSI Class IV shutoff.

- Fail closed.

Combustion Technology, LLC

800-327-1831

https://combustion-tech.net