This blog will present application solutions and equipment used in process heating. Components such as temperature controls, thermocouples, gas pressure regulators and flow meters, to complete industrial burner systems will be discussed. We hope to educate on current technologies, introduce unique process heating applications, and present new industrial heating/process products. For more, please visit Combustion Technology or call 800-327-1831.

The Role of Modulating Valves in Industrial Combustion

800-327-1831

Surplus Inventory Listing Added to Combustion Technology Website

Experts in Industrial Combustion Airflow Management

Contact Combustion Technology with Your Natural Gas Fired Industrial Boilers and Package Boilers Applications

Assistance with Your Power, Biomass, and Recovery Boiler Needs

Decades of Experience with Heaters, Furnaces, Ovens, and Kilns

800-327-1831

Wiring the Siemens Combustion Controls SQM4 Synchro for 4-20 mA Modulation

SQM4 SYNCHRO FEATURES

- NEMA 4 – No need for weather shields

- No restrictions on mounting orientation – No more elaborate linkages to keep the shaft horizontal!

- The modulating input versions accept 2-10 Vdc, 4-20 mA or 0-135 ohm control signals

Combustion Technology Distributes Pietro Fiorentini Gas Regulators in Pacific Northwest

- GOVAL Line Pressure Regulator

- Governor

- Dival 600

- Trias

- Dival 160 AP

- Dival 500

- VS/AM 65

- VS/AM 58

- Aperval

- SCN Slam Shut

- Aperval 101

- Aperflux 101

- Governor 2 PSIG

- Dilock Safety Device

- Aperflux 851

- Governor Dual Cut 10 PSIG

- PVS 782 Slam Shut

- Zero/Ratio GOVERNOR Regulators

- Governor PF400 Outdoor

- PVS 803 Slam Shut

- Governor PF400 Vertical Vent Limiter

- Governor PF400 Vent Limiter

- Mod FE

- Mod FEX

- Norval

- Cirval

- Reflux 819

- Reval 182

- HBC 975

- Staflux 185

- SBC 782 Safety Device

- Staflux MINI

Phoenix Velocity Heat (VH) Direct Fired Burners: 500,000 up to 2,000,000 BTU/hr

You Don’t Have to accept 6 month lead times fromother direct burner manufacturers!

Flame Scanners and Detectors

800-327-1831

The Siemens Combustion Controls LFS1 Flame Detection Switch

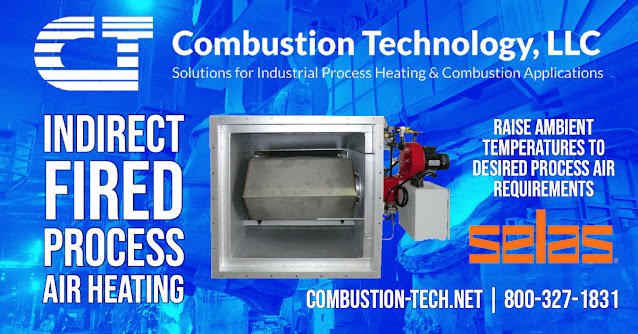

Indirect Fired Process Air Heater for Raising Ambient Temperatures to the Desired Process Air Requirements - The Selas HEM

The Selas HEM Indirect Fired Process Air Heater - Designed to fire applications where process air needs to be heated from ambient temperatures to the process plant’s heat requirements.

Selas HEM Indirect Fired Process Air Heater Operating Principles

- Fully modulating, indirect firing burner

- Pre-packaged and pre-wired burner assembly

- High temp limit thermostat or thermocouple unit

- High-grade stainless steel combustion chamber

- Operates on natural gas, LP or light fuel oil

- Ideal for shopping centers & commercial premises

- Ready for drop-in installation

- Protects the heat exchanger from overheat

- Durable construction for long life

- Installation not dependent on single fuel source

Process Heating and Control for Hemp Drying and Hemp Oil Processing

Hemp was legalized as part of the 2018 Farm Bill, transforming it from a controlled substance to an agricultural commodity. Farmers whose tariff increases have impacted certain crops find hemp cultivation appealing. Consumer demand, combined with higher farm profits, is driving explosive growth. Hemp cultivation occurs for seed, fiber, or floral biomass.

After harvest, the hemp needs to be immediately transported to a drying facility to remove the moisture content. Hemp harvesting and drying are critical steps in CBD production. Molds and mildews associated with moisture reduce the value of floral hemp biomass, so the harvest needs stabilization before mold, mildew, or decomposition can occur.

Air drying small batches of hemp in a barn makes sense despite its inefficiency and slowness, but more modern and systematic approaches to drying are required to meet consumer demand for large batches. New industrial dryers with capacities ranging from 1000 to 4000 pounds of biomass per hour and total drying control are available to meet this skyrocketing demand.

Batch dryers have drying chambers that typically include a dehumidifier, an aerator, and a heat source. The energy-efficient dehydration systems for drying hemp are closed systems that operate independently of ambient conditions. Combining the heat-driven dehumidification unit, a programmable controller, and airflow equipment result in consistent drying conditions inside the chamber.

Belt dryers include a conveyor that leads into a large drying chamber. Mesh-belt hemp dryers continuously dry large quantities of biomass in a short time without requiring a large production footprint. Belt dryers enable an operator to fine-tune the hemp dryer's thermal energy to evaporate moisture without over-drying or overheating the hemp. Belt dryers use propane or natural gas as their heat source with high BTU output. Belt dryers also use electronic controls for precise biomass drying and optimize combustion efficiency.

Rotary dryers have been the workhorse of industrial dryers for many years. They also work well for drying hemp and typically use natural gas as their heat source. The biomass goes in a heated cylinder, which rotates and tumbles the material in the presence of hot, dry air. Plates on the inside of the cylinder, or drum, move the hemp through the drum, and sophisticated electronic combustion controls regulate temperature and time for the drying process.

Legacy custom oven and furnace manufacturers are finding a new, lucrative market for hemp dryers and hemp oil processing, considering the technology and fabrication process are nearly identical to the custom furnace and kiln development. Burners, controls, and gas valves are all standard components. A critical piece for success in developing a successful hemp drying strategy is to work closely with an expert in process heating, combustion, and control systems. Their breadth of experience and engineering skills will contribute to positive outcomes.

For expert advice on process heating and control systems specifically for hemp oil processing and hemp drying, contact Combustion Technology, LLC. Their experience in combustion optimization, thermal profiling, and temperature measurement is premier. They have equipment and instrumentation ready to provide the high-level performance required for the hemp processing industry, such as:

- Wide turndown burners with precise temperature control.

- Modulating gas control valves with .1 of a degree positioning accuracy.

- Process controllers and indicators are accurate to .25% of span.

- 508A listed electrical panels, NFPA 86 compliant

- Secure digital recording of temperature and other critical variables for contract drying.

Headquartered in the Pacific Northwest, reach them by calling 800-327-1831 or visiting their website at https://combustion-tech.net.