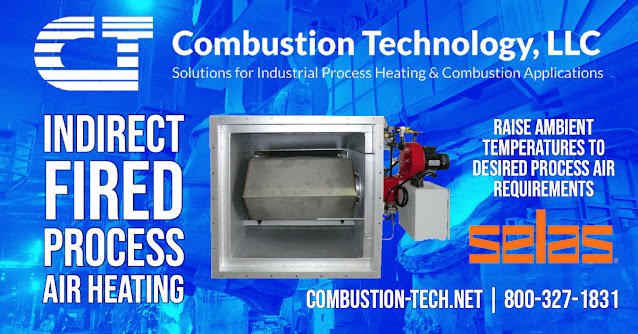

The Selas HEM Indirect Fired Process Air Heater - Designed to fire applications where process air needs to be heated from ambient temperatures to the process plant’s heat requirements.

Selas HEM Indirect Fired Process Air Heater Operating Principles

Burner Assemblies

Each HEM unit is supplied with a pre-packaged and pre-wired burner assembly which includes all of the necessary burner fuel safety valves, pressure switches and automatic ignition and flame safety equipment. Most types of flame failure and automatic ignition control units can be supplied, utilizing flame rectification, photo cell or ultra-violet flame sensing equipment. Air heating burners built to specific applications and country of installation can be fitted. All Burner packages are fully tested and the operation of all components are checked before dispatch from the factory.

Fuel Supply

Burners can be fitted for operation with natural gas, LP gases or light fuel oils. All gas burners are sized to suit an inlet gas pressure of 17.5mbar (natural gas) or 30mbar (LP gases) unless otherwise specified. Burners can be supplied to suit other fuel types and supply pressures.

Direction of Air Flow

Standard HEM process air heaters are arranged to fire horizontally in the direction of air flow from left to right. Heater units can be supplied for firing into duct systems with vertical upwards or downwards air flow. Air flow should be uniform across the air duct, both upstream and downstream of the heater.

Electrical Supply

The HEM units can be fitted with burners to suit almost all types of electrical supply, including all common industrial three phase (50 or 60Hz) power supplies. Burners can be supplied to accommodate electrical voltages for specific applications and destinations.

Features

- Fully modulating, indirect firing burner

- Pre-packaged and pre-wired burner assembly

- High temp limit thermostat or thermocouple unit

- High-grade stainless steel combustion chamber

- Operates on natural gas, LP or light fuel oil

Benefits

- Ideal for shopping centers & commercial premises

- Ready for drop-in installation

- Protects the heat exchanger from overheat

- Durable construction for long life

- Installation not dependent on single fuel source

For more information about Selas products in the Pacific Northwest, contact Combustion Technology, LLC. Call 800-327-1831 or visit https://combustion-tech.net.